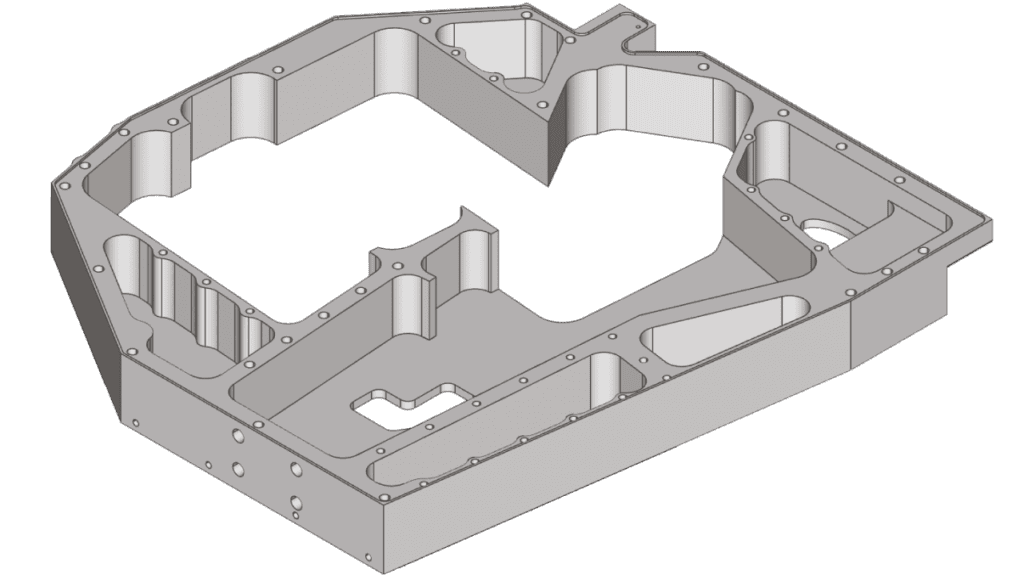

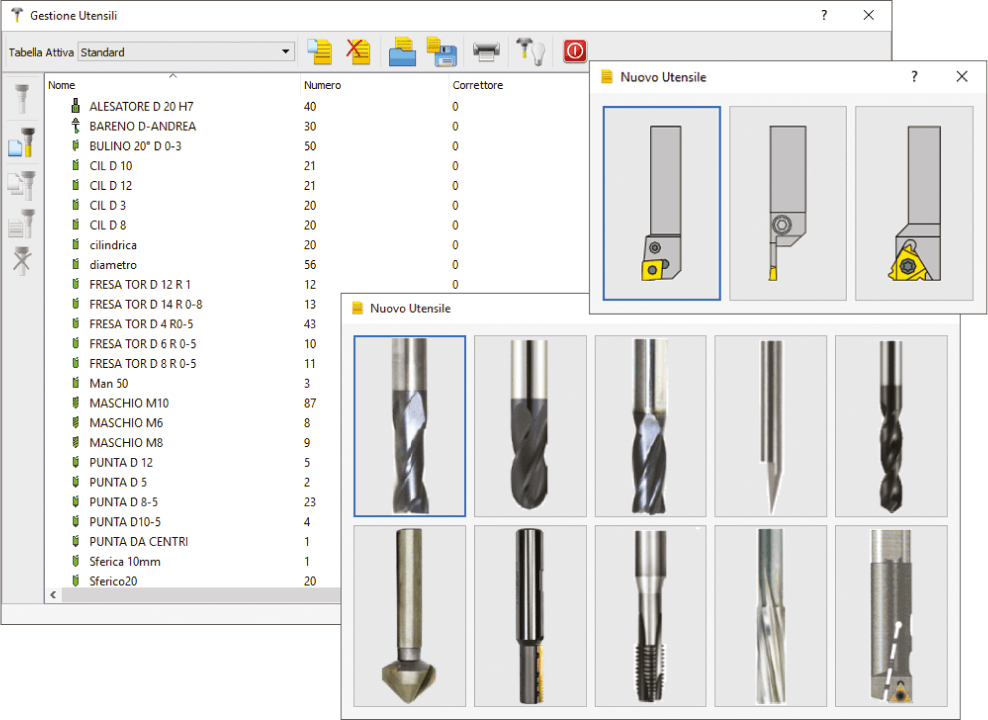

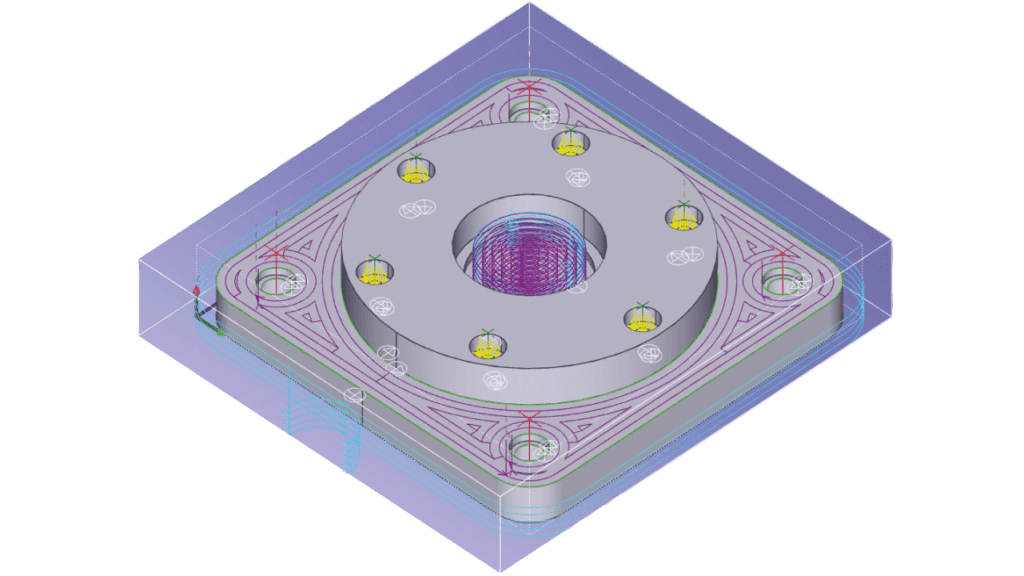

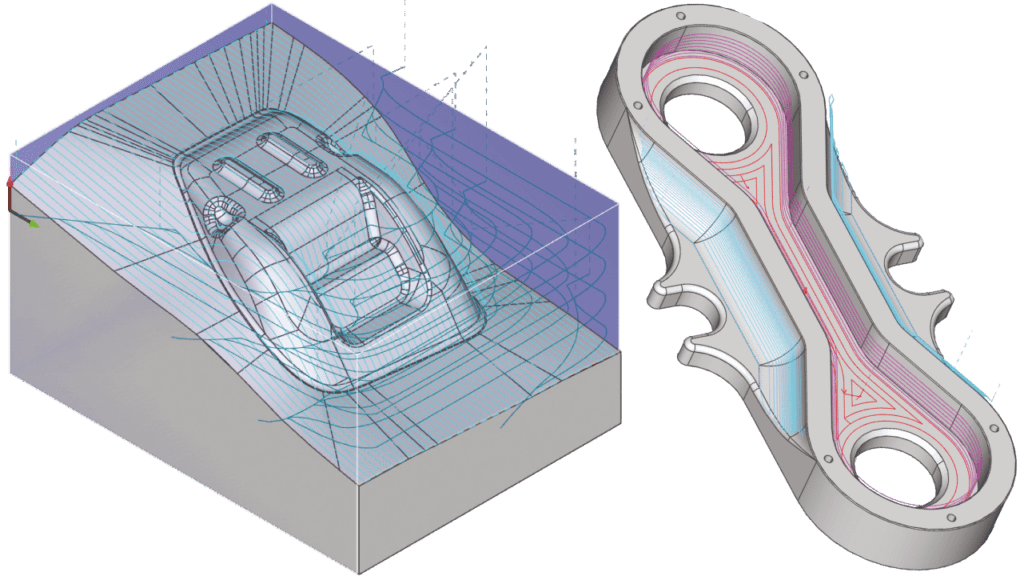

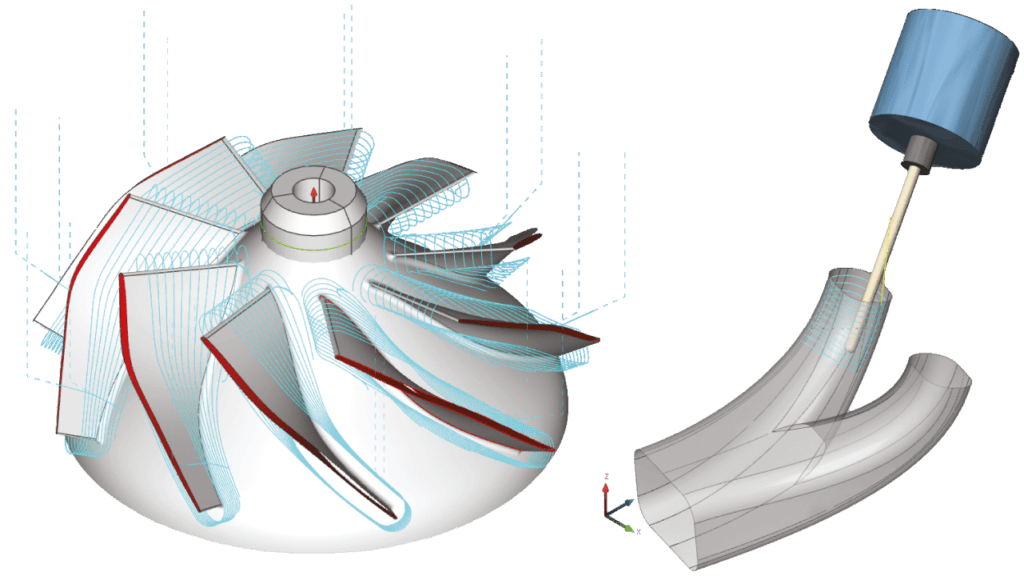

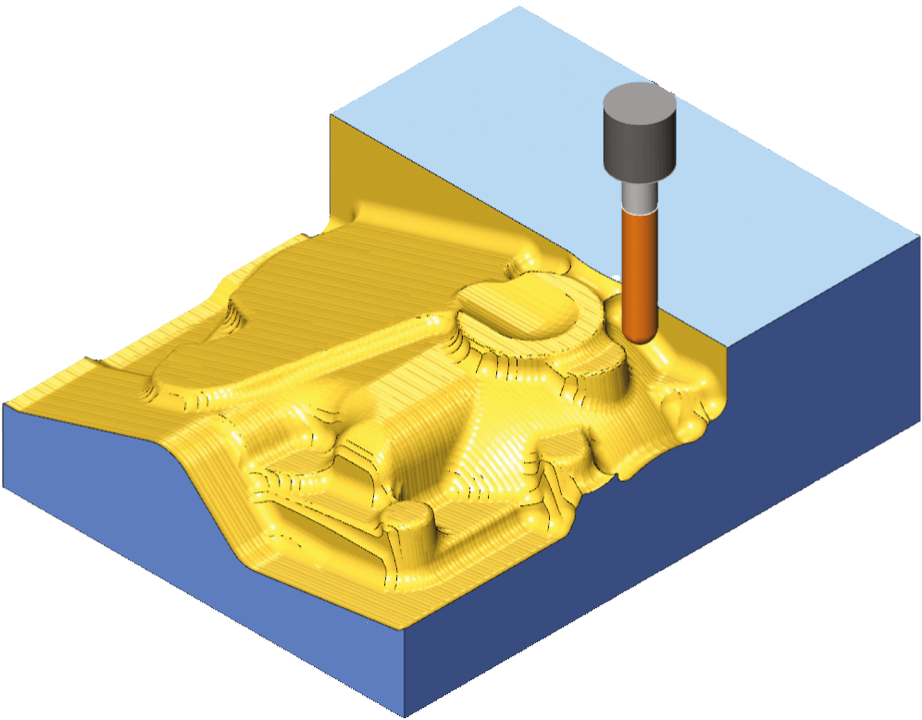

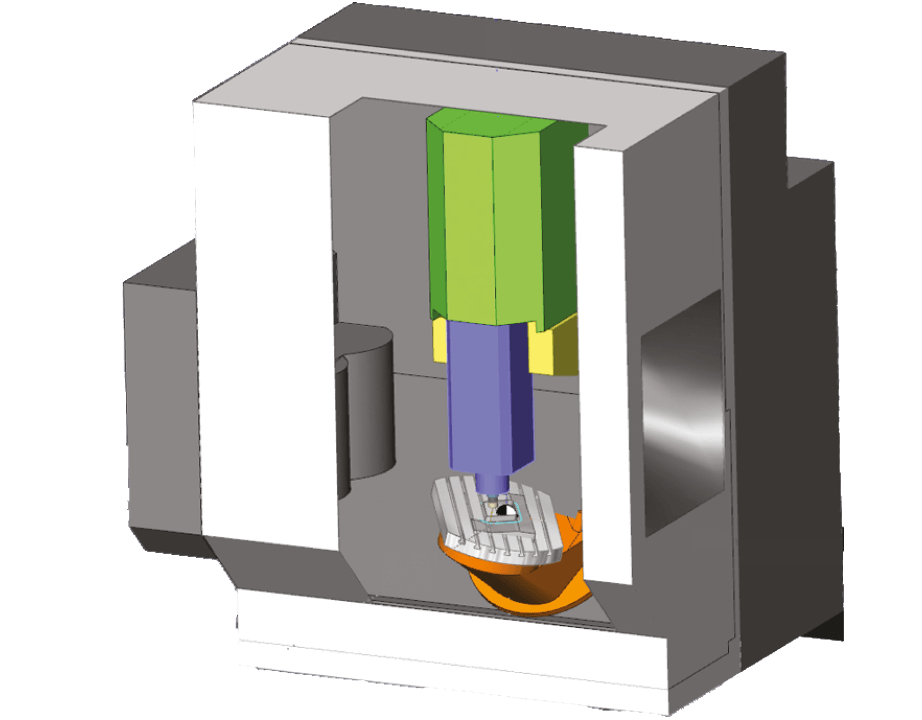

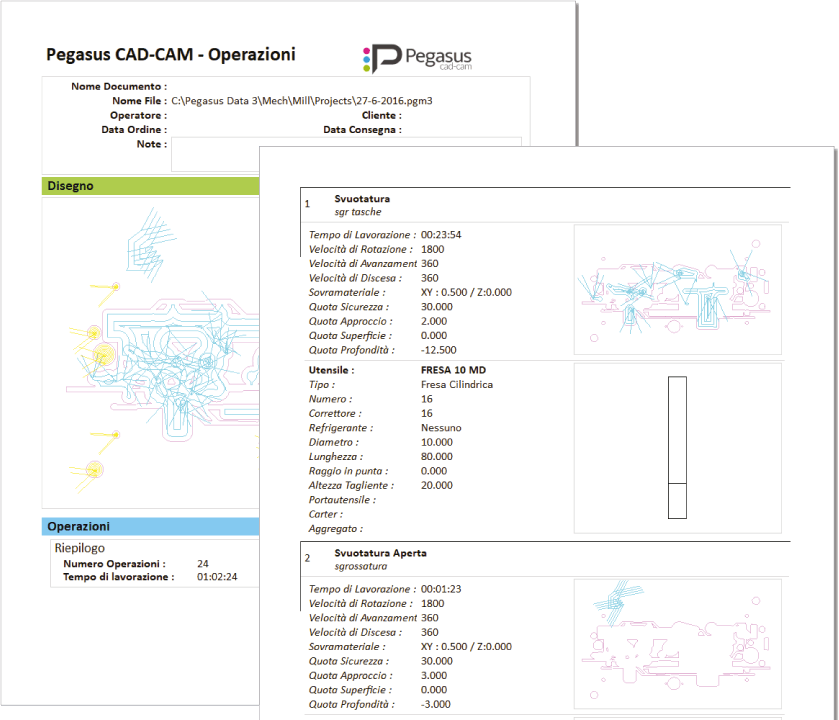

Software suitable for both milling and lathe machines, it can be used with compound rotary tables as well as more complex 5 continuous axes machining centers. Simple and intuitive, it needs no advanced technical skills to be used and comes with online help to support the user at all phases of the process.

![]() download the brochure

download the brochure

Stay informed, you'll always be one step ahead!

Subscribe to our Newsletter and receive the most important news and exclusive offers.